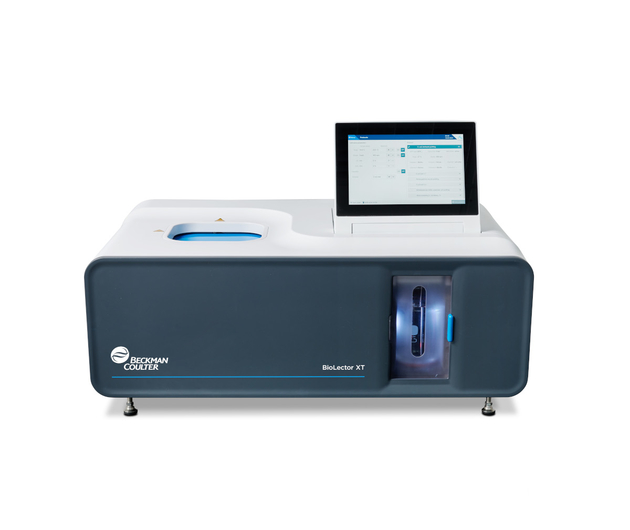

BioLector XT High Throughput Microbioreactor

Description

BioLector XT

High-throughput microbioreactor enables real-time evaluation of biomass, fluorescence, pH, DO, and other key cultivation parameters for aerobes and anaerobes.

This microbioreactor is based on a standard ANSI/SLAS (SBS) microtiter plate (MTP) format, and operates with online, pre-calibrated optical sensors. Disposable 48 well MTPs enable online measurement of cultivation parameters, while patented microfluidic technology supports simultaneous pH control and feeding. The optional microfluidic module eliminates manual liquid handling—no tubing or pipetting required, as everything is part of the gamma-radiated ready-to-use plate.

| FEATURES AND BENEFITS | |||

| Innovative Gassing Lid | Optional Microfluidic Module | “Plug-And-Play” Plate Design | Intelligent Biolection Software |

| Enables fed-batch experiments under anaerobic conditions | Microvalves allot liquids at nanoliter-scale | Online data out of 48/32 parallel cultivations | Intuitive user interface supports multi-user environments |

| Gassing with O22within a range of 1% – 100% and with CO2 within 0% – 12 % | Complements online monitoring function with well-specific pH regulation/feeding | Customizable feeding strategies (batch, fed-batch)* | Free programming of all control parameters |

| Reduces gas consumption to a few mL/minute | Enables use of 2 feed lines per cultivation well | Control of pH on-the-plate with pre-calibrated optical sensors* | Open system enables live data downloads |

| Optional humidification of gases reduces evaporation | Small working volume (800 – 2400 μL) | Fast processor ensures rapid download of experiment data | |

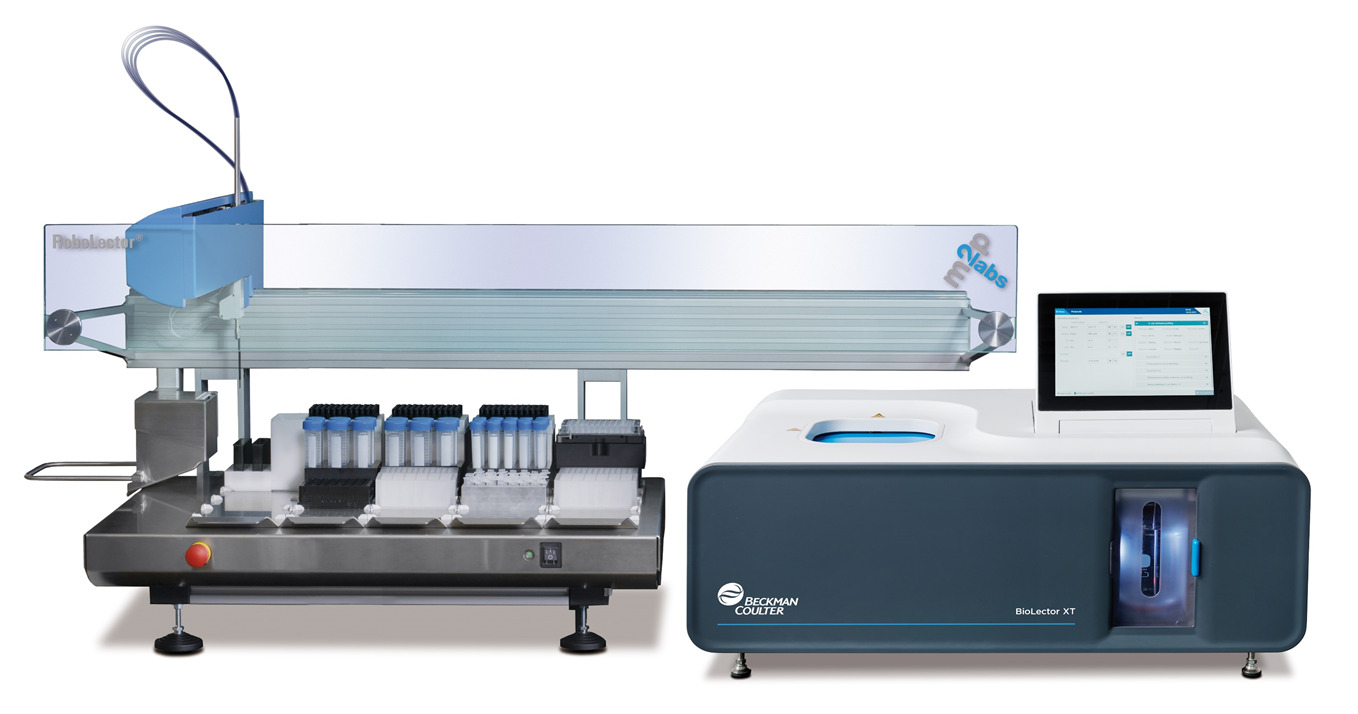

Automated Fermentation

For triggered sampling, harvesting or additional feeding, the BioLector XT can be combined with a liquid handling robotic system. Check out below for more details on RoboLector

RoboLector®

RoboLector® is a proprietary combination of a liquid handling robot with a BioLector®.

This unique automated fermentation platform integrates the high-throughput fermentation and online

monitoring capability of the BioLector® with the precise liquid handling of a robotic system.

| FEATURES | |||

| Fermentation Modes | Online Trigger Signals | ||

| • DO or time controlled feeding • Fed-batch with bolus feeding • Repeated fed-batch • Biomass dependent sampling or dosing • Time dependent sampling or dosing • pH adjustments |

• Biomass concentration • pH, DO (using optodes) • Fluorescent molecules (GFP, YFP, DsRed …) • NAD(P)H and ribofl avins • Process or induction time • Working volume |

||

| ADVANTAGES | |||

| • Automated upstream processing of up to 48 parallel fermentations • Continuous operation 24 hours/day and 7 days/week • Plug & Play disposable technology • Design of experiments (DoE) • Detailed process understanding in short time • Excellent pipetting accuracy (< 5 %, 50-950 µl) and reproducibility (CV < 5 %, 50-950 µl) • Reliable scale up to lab-fermenters • Fast and easy data analysis • A valuable tool for PAT and QbD • Processing units possible (for custom made solutions) |

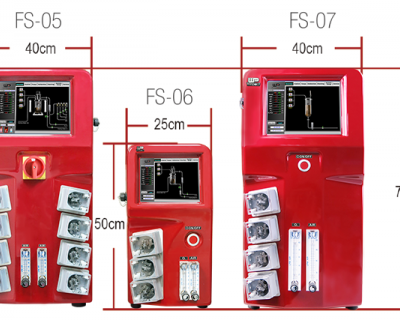

| AVAILABLE IN 2 SIZES | ||||

| RoboLector® L | RoboLector® XL | |||

| Robotic Arms | 1 | 1 | ||

| Arm Type | Liquid handling | Liquid handling | ||

| Pipetting Channels | 2 or 4 | 8 | ||

| Pipetting Volume With Disposable Tips | 20 – 950 µl | 20 – 950 µl | ||

| Pipetting Volume With Washable Tips | 10 – 1000 µl | 10 – 1000 µl | ||

| Liquid Level Detection | By capacity in conductive liquids | By capacity in conductive liquids | ||

| Type Of Tips | 1 disposable tip, 1 washable tip (L-2) & 1 disposable tip, 3 washable tips (L-4) | 2 disposable tips, 6 washable tips (XL-8) | ||

| Max. Deck Positions (SBS footprint) | 16 | 20 | ||