Description

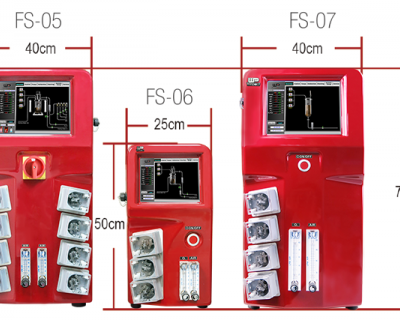

The 10L / 30L / 50L SIP Pilot Scale Fermentation Systems allow you to run small volume of fermentation experiment with ease. These systems are perfectly suitable for small scaling up in the academic lab. The easy programming and operation on our Winpact software put your operation procedure in your peace of mind. System comes with rolling wheels for mobility. All materials are made from the highest standard to ensure optimization of your fermentation process. A variety of optional devices are also available for selection to maintain your optimum performance.

A.Harvest valve: sterilizable, diaphragm-type tank bottom valve for sanitary post-process harvest

B.Sampling valve: steam-sterilizable valve permits repeatedly sanitary sample collection

B1.Motor – Manual or automatic control of constant agitation speed.

B2.Stainless Steel – Vessel Special designed heating jacket provides better heating efficiency

B3.Peristaltic Pump – Uses four Watson Marlow built-in peristaltic pumps for all your feeding needs

B4.Control Station – Large screen and graphical user interface

Major Science SIP Fermentation Systems

- Wide range of vessel selection, from 10L to 50L working volume

- Colorful interface at 10.4″ or above

- Fully automated process with remote monitoring

- 15-step automatic program setting

- Orbital welding ensures minimal residue buildup

- Highest grade construction with 316L stainless steel

- Jacket design provides astounding temperature control

- Exhaust pressure relief valve for maximum safety precaution

- Multiple safety design integration for peace of mind operation

- Remote monitoring & controlling software free from purchase

- Password protection for multiple users with special requirements

- Various optional devices for process optimization and needs

- Ethernet communication with Winpact SCADA software, and IP address

|

|

|

| Four-staged DO cascade | ||

|

||

| 15-Step programmable PID control | Immediate visualization on operation overview | Easy and intuitive operation for manual and sequence control |

|

|

|

| One-Touch automatic sterilization for

vessel and system tubing |

Online system calibration with

system feedback |

System expansion with various

optional devices |